Essential Maintenance: Tips for Expanding the Lifespan of Komatsu Undercarriage Parts

Essential Maintenance: Tips for Expanding the Lifespan of Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Parts for Heavy Equipment

Quality undercarriage components play a significant function in ensuring the smooth operation and long life of heavy equipment. In this discussion, we will certainly check out the importance of spending in superior undercarriage parts, usual wear obstacles encountered by hefty machinery operators, the advantages of prompt replacements, guidelines for picking dependable vendors, and important upkeep tips to prolong the life-span of undercarriage parts.

Importance of High Quality Undercarriage Components

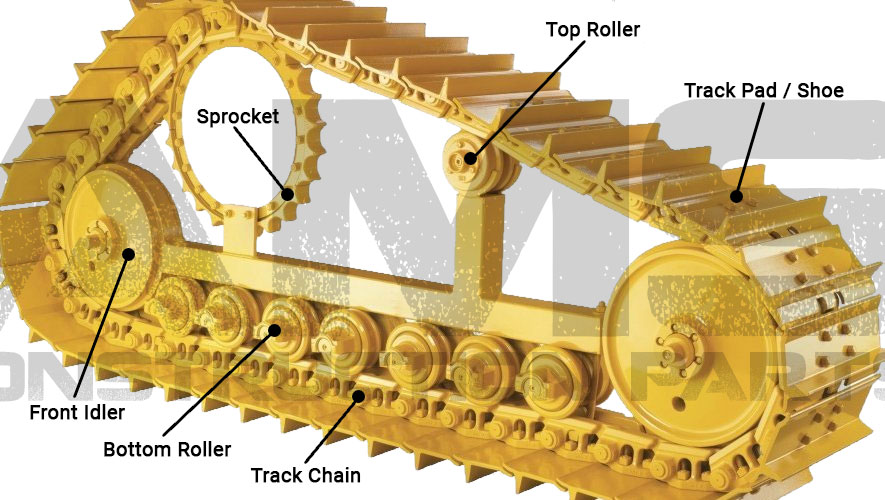

Quality undercarriage parts are crucial components in guaranteeing the sturdiness and efficiency of heavy equipment. The undercarriage of tools such as excavators, excavators, and track loaders plays an important duty in sustaining the device's weight, providing stability on various terrains, and absorbing the impact of uneven surfaces. By investing in top quality undercarriage parts, operators can substantially prolong the life expectancy of their equipment and lower the threat of unanticipated failures.

One key benefit of making use of top quality undercarriage parts is the improvement of total machine performance. Durable tracks, rollers, sprockets, and idlers minimize rubbing and guarantee smoother activity, ultimately bring about boosted performance and performance on task websites. Dependable undercarriage parts minimize downtime for maintenance and fixings, permitting drivers to optimize their functional hours and task due dates.

Common Undercarriage Put On Issues

Benefits of Timely Substitute

One secret benefit of timely undercarriage part substitute is raised equipment uptime. By changing used parts before they fail, the risk of unexpected failures is decreased, lowering downtime for fixings and upkeep. This positive method not only maintains the hefty machinery operational yet additionally see this page protects against possible damage to other components that can arise from a stopping working undercarriage.

In addition, changing undercarriage components promptly can boost total performance. A properly maintained undercarriage makes certain ideal equipment efficiency, permitting for smoother procedure and greater performance in completing tasks. This, in turn, brings about boosted job website efficiency and cost financial savings by preventing hold-ups and disruptions triggered by Find Out More underperforming equipment. Spending in timely undercarriage part substitute is a positive method that pays off in terms of boosted performance and lowered operational prices.

Choosing the Right Undercarriage Vendor

Picking the ideal undercarriage vendor is an important decision that considerably impacts the efficiency and maintenance of heavy equipment. When selecting a provider for undercarriage parts, numerous variables need to be taken into consideration to guarantee optimum efficiency and cost-effectiveness. A vendor that offers a broad choice of undercarriage parts for numerous heavy equipment brand names and models can be useful as it offers extra choices to meet certain needs.

Stabilizing reliability, cost-effectiveness, and quality is crucial when choosing the best undercarriage provider for heavy equipment. By carefully evaluating these elements, you can choose a distributor that satisfies your demands and adds to the effective performance and maintenance of your hefty machinery.

Maintenance Tips for Extended Life-span

To make certain an extended life expectancy for heavy equipment undercarriage components, applying a proactive maintenance routine is vital. Investing in top quality undercarriage parts from trusted vendors is try these out equally essential for making sure durability. By complying with these upkeep ideas faithfully, hefty equipment proprietors can enhance the performance and sturdiness of their undercarriage parts, eventually decreasing downtime and operational prices.

Final Thought

In verdict, quality undercarriage components are crucial for the reliable operation of hefty equipment. Selecting a reputable provider and adhering to correct maintenance practices are essential to making certain the expanded lifespan of undercarriage elements.

Too much wear and tear on undercarriage parts of heavy machinery can lead to considerable operational difficulties and raised maintenance expenses. Routine examinations, correct maintenance, and prompt replacements of worn undercarriage components are crucial to reduce these typical wear issues and make sure the optimum functioning of heavy machinery.

A supplier that provides a wide selection of undercarriage components for numerous hefty machinery brands and models can be advantageous as it gives more choices to meet certain requirements.

By complying with these upkeep ideas diligently, heavy equipment proprietors can enhance the performance and resilience of their undercarriage parts, eventually lowering downtime and functional prices.

Report this page